Are you trying to figure out how to advance your company? Choose 3D laser cutting Melbourne services without a second thought. This cutting-edge technology is revolutionising the industrial sector by making it simple for companies of all sizes to produce elaborate and precise designs. As a means of streamlining their manufacturing procedures and staying one step ahead of the competition, more and more businesses in Melbourne are using 3D laser cutting. Continue reading to find out why Melbourne firms are using this technology more frequently and how you can profit from it too!

What exactly is a 3D laser cut?

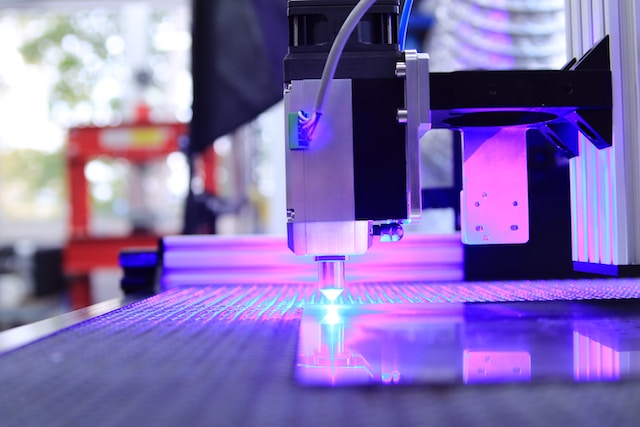

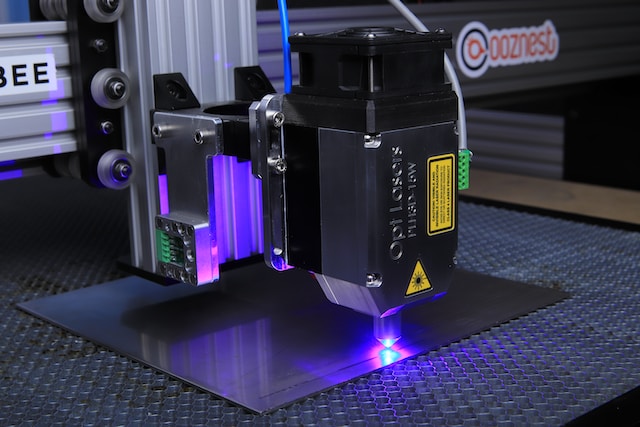

A focused, highly-powered laser beam is used in 3D laser cutting, a sort of industrial technique, to accurately and precisely cut through diverse materials. In contrast to conventional cutting techniques, which depend on actual blades or drills, 3D laser cutting makes precise cuts in intricate forms and designs using computer-controlled machinery.

The adaptability of 3D laser cutting is one of its main advantages. It can be applied to a variety of substances, such as metals, polymers, wood, and even fabrics. This makes it the perfect option for companies in a variety of sectors, from aerospace to fashion.

The quickness and effectiveness of 3D laser cutting is another advantage. It can swiftly make vast numbers of identical parts without any variances or mistakes because it is computer-controlled.

Overall, 3D laser cutting has a lot of benefits over conventional production processes. Due to its accuracy and adaptability, it is becoming a more and more common option among Melbourne organisations seeking to enhance their production procedures and compete in the market of today.

How Businesses are Using 3D Laser Cutting?

Due to its adaptability and precision, businesses are turning more and more to 3D laser cutting services. Numerous industries, including manufacturing, automotive, healthcare, and even aerospace, are using the technology.

Prototyping is one of the most important uses of 3D laser cutting in industry. With the help of this technology, businesses can swiftly produce prototypes with precise measurements and intricate shapes. As a result, they can test their concepts before moving forward with mass manufacturing.

Custom manufacturing is another application for 3D laser cutting. Using the technology’s precision cutting capabilities, businesses may quickly produce distinctive goods that satisfy certain client specifications. This has increased demand for customised products in a variety of industries.

Intricate patterns can also be made on a variety of materials, like metal or wood, by using 3D laser cutting services. These patterns improve a product’s visual appeal while simultaneously providing practical advantages like increased grip or lighter weight.

Because 3D laser cutting offers unmatched accuracy and versatility compared to other conventional methods, businesses are increasingly flocking to these services. We can anticipate additional cutting-edge applications that will further revolutionise how organisations work in the future as technology continues to advance quickly.

The Advantages of Using Services for 3D Laser Cutting

There are many advantages to using 3D laser cutting services for your organisation. First off, it enables precise cuts that are challenging to do using conventional techniques. Due to the utilisation of cutting-edge technologies, the accuracy is unmatched.

Increased productivity is another advantage of 3D laser cutting because it uses less material and requires less setup time than conventional cutting techniques. Additionally, it makes it simpler to correctly and distortion-free cut intricate forms and patterns.

Additionally, 3D laser cutting offers quicker turnaround times, which reduces the amount of downtime for firms while they wait for their products. As a result, overall production levels increase.

Additionally, adopting such services might result in cost savings because fewer workers are needed during manufacturing runs, which results in lower labour expenses. Additionally, businesses can outsource these tasks rather than investing in costly equipment or maintenance.

Due to the usage of computer-generated designs, 3D laser cutting offers greater design freedom, giving businesses more creative control over their projects and helping them stand out from the competition by providing one-of-a-kind solutions that are especially suited to the needs of the clients.

How to Begin Using Services for 3D Laser Cutting?

Here are the several advantages of 3D laser cutting services for Melbourne companies. It makes sense that more businesses are using this technology to enhance their manufacturing procedures.

The first step in beginning to use 3D laser cutting services is to determine your unique needs and objectives. Find a respectable business that provides top-notch services for a fair price. Inquire about their qualifications, equipment capabilities, and customer service practices.

Work carefully with the provider you’ve chosen to define the precise details of your project. Make sure you offer thorough drawings or models so the laser cutter can be programmed correctly. Ask about any additional processes or post-processing requirements needed for finishing touches as well.

Using 3D laser cutting services may be a good investment for your company, one that pays off in enhanced productivity, precision, and high-quality products, with careful planning and experienced direction from a dependable source.